1066 NAGAO High Speed Press

Price 1200000 INR/ Unit

1066 NAGAO High Speed Press Specification

- Material

- Mild Steel

- Power

- 1 HP

- Voltage

- 220V / 380V

- Dimension (L*W*H)

- 900 x 800 x 1900 mm

- Product Type

- HIGH SPEED PRESS

- Application

- Sheet Metal Forming

- Accessories

- Die set, Lubrication System

- Stroke Length

- 60 mm

- Shut Height

- 220 mm

- Capacity

- 10 Tons

- Frame Type

- C Frame

- Max. Pressing Speed

- 200 Strokes/min

- Motor Speed

- 1400 RPM

- Ram Adjustment

- 40 mm

- Bed Size

- 600 x 350 mm

1066 NAGAO High Speed Press Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Main Domestic Market

- All India

About 1066 NAGAO High Speed Press

HIGH SPEED PRESS

NAGAO JAPAN

MODEL: NCP-80

SKU # 1066

Brief Specifications/ Details

- Cap: 80Tons

- Stroke: 30mm

- Bed Size: 1000 x 600mm

- Ram Size : 540 x 400mm

- Die Height: 440mm

- Adjustment: 75mm

- SPM: 150

Versatile Press for Metal Forming

The 1066 NAGAO High Speed Press excels in a range of metal forming applications, thanks to its adjustable ram, robust shut height, and quick stroke rate. Both small and medium manufacturers can leverage this press for efficient and consistent production, supported by durable mild steel construction and advanced accessories.

Powerful and Efficient Operation

With a powerful 1 HP motor and a pressing speed of up to 200 strokes per minute, the press delivers both speed and precision. Its C-frame structure ensures accessibility and strength, while the included lubrication system and die set enhance productivity and machine longevity.

FAQs of 1066 NAGAO High Speed Press:

Q: How do I operate and adjust the 1066 NAGAO High Speed Press?

A: To operate the 1066 NAGAO High Speed Press, ensure the power (220V or 380V) is connected and the press is securely positioned. Adjust the ram using the 40 mm ram adjustment feature to set the desired stroke length for your task. Always confirm the die set is properly installed, and activate the built-in lubrication system before starting production.Q: What types of jobs or materials is this high speed press suitable for?

A: This press is specifically designed for sheet metal forming and works efficiently with mild steel and similar metals. Its 10-ton capacity and 600 x 350 mm bed make it suitable for producing automotive parts, appliance components, electrical enclosures, and various stamped or formed metal items.Q: When should I use the lubrication system provided with the press?

A: The lubrication system should be used before and during each production session to prevent excessive wear and ensure smooth operation. Regular lubrication maintains optimal machine performance, reduces the risk of breakdowns, and prolongs both the press and die set lifespan.Q: Where is the best location to install the 1066 NAGAO High Speed Press in my workshop?

A: Install the press on a stable, level surface with adequate clearance for both operation and maintenance. Ensure sufficient space around its 900 x 800 x 1900 mm dimensions and provide good ventilation and access to electrical supply lines. This setup enhances safety and operational efficiency.Q: What is the process for changing the die set on this press?

A: To change the die set, disconnect the power supply, ensure all moving parts have stopped, and safely remove the existing die using standard lifting or handling tools. Carefully align the new die set with the ram and bed, secure it tightly, and check alignment before resuming operation.Q: How does the C frame design benefit pressing operations?

A: The C frame design offers increased accessibility from the front and sides, making it easier to load materials and change die sets. This structure also enhances operator comfort and allows for better integration into automated or manual production lines, streamlining workflow.Q: What are the main benefits of using the 1066 NAGAO High Speed Press in manufacturing?

A: Using this high speed press increases production efficiency due to its rapid operating speed, reliable power, and adaptable settings. Its sturdy construction, versatile die compatibility, integrated lubrication, and user-friendly controls help deliver consistent, high-quality results with reduced downtime and maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Speed Press Category

KYORI Used High Speed Press

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : KYORI Used High Speed Press

Material : Mild Steel

Application : Industrial

KYORI PSV-3 Used High Speed Press

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : KYORI PSV3 Used High Speed Press

Material : Mild Steel

Application : Industrial

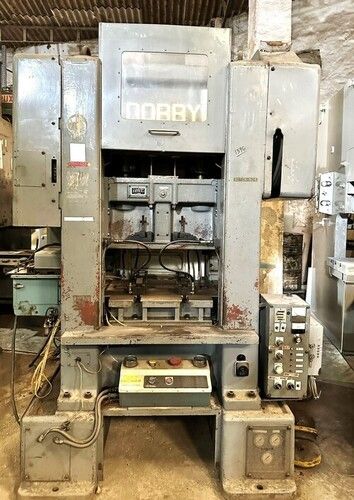

1396 DOBBY HIGH SPEED PRESS

Price 1800000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : HIGH SPEED PRESS

Material : Mild Steel

Application : Industrial Sheet Metal Pressing

Dimension (L*W*H) : 1100 x 950 x 1850 mm

1403 DOBBY HIGH SPEED PRESS

Price 2850000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : HIGH SPEED PRESS

Material : Mild Steel

Application : Textile Industry Dobby Attachment and Processing

Dimension (L*W*H) : 1030 x 490 x 1430 mm

|

MARVEL MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry