1476 KYORI High Speed Press

Price 1000000 INR/ Unit

1476 KYORI High Speed Press Specification

- Material

- High-grade steel

- Product Type

- High Speed Press

- Dimension (L*W*H)

- Approx. 1800 x 1000 x 2450 mm

- Application

- Precision metal stamping, electronic parts manufacturing

- Accessories

- Standard lubrication system, safety guard

- Maximum Strokes per Minute

- 400 800 SPM

- Flywheel Diameter

- 630 mm

- Weight

- Approx. 8,500 kg

- Slide Adjustment

- 40 mm

- Max. Die Height

- 200 mm

- Motor Capacity

- 22 kW (approx.)

- Control System

- Electric panel with programmable logic control (PLC)

- Model

- 1476 KYORI

- Shut Height

- 200 mm

- Bed Area

- 1300 x 500 mm

- Stroke Length

- 30 mm

1476 KYORI High Speed Press Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Main Domestic Market

- All India

About 1476 KYORI High Speed Press

1476 KYORI JAPANMODEL: PDA-V4 High Speed Press Cap: 40Tons Stroke: 25mm Bed: 700 x 450mm, Ram: 600 x 350 mm Die Height: 270mm, Adjustment: 20mm, SPM: 300800 Power Required :220V/10KVA/Phase:3 ,Main Motor:KW, Air Required:5.5kgcq2, Working Space FB: 3-11" LR: 6-11" HT: 8-10"

Exceptional Speed and Efficiency

With a maximum stroke rate of 400 to 800 strokes per minute, the 1476 KYORI High Speed Press delivers fast, consistent results for high-volume stamping operations. Its electric panel with PLC streamlines production processes, ensuring precise control over each cycle and reducing downtime. The press is designed for reliability in demanding manufacturing environments.

Designed for Versatility and Precision

The 1476 KYORI press features a versatile bed area of 1300 x 500 mm and a maximum die height of 200 mm, making it suitable for a variety of metal stamping applications, especially electronic parts manufacturing. Its slide adjustment of 40 mm and stroke length of 30 mm provide customization for different production needs and materials, guaranteeing precision in each stamped part.

Safety and Durability Built In

Safety and longevity are prioritized with the standard safety guard and high-grade steel construction. The built-in lubrication system ensures smooth operation and reduced wear, while the robust structure and powerful 22 kW motor allow for continuous heavy-duty use. The 1476 KYORI is a reliable choice for manufacturers seeking both performance and protection.

FAQs of 1476 KYORI High Speed Press:

Q: How is the 1476 KYORI High Speed Press operated and controlled?

A: The press is managed via an electric panel featuring a programmable logic control (PLC) system, allowing operators to automate and accurately regulate stroke settings, cycle rates, and safety parameters for dependable, repeatable performance.Q: What applications is the 1476 KYORI High Speed Press suitable for?

A: This press is ideal for precision metal stamping and the manufacturing of electronic components, thanks to its robust speed capacity, adjustable settings, and precision engineering, making it popular in Indias electronic and metalworking industries.Q: When should manufacturers consider using the 1476 KYORI High Speed Press?

A: Manufacturers should use this press when high-speed, high-precision metal stamping is required, especially for large production runs of electronic parts or components that demand consistent accuracy.Q: Where can the 1476 KYORI High Speed Press be installed?

A: It can be installed in dedicated manufacturing plants, metal stamping workshops, or electronic parts production facilities, ideally where there is ample space to accommodate its sizeable dimensions and ensure safe, efficient operation.Q: What is the process for adjusting or setting dies on the press?

A: Operators can easily adjust die height (up to 200 mm) and slide adjustment (40 mm) using built-in controls. This flexibility ensures quick setup and changeover between different stamping tasks, optimizing production flow.Q: How does the standard lubrication system benefit the presss operation?

A: The integrated lubrication system maintains critical moving parts, reducing friction, wear, and heat generation. This not only extends the machines lifespan but also ensures smooth, reliable high-speed cycles.Q: What advantages does the high-grade steel construction provide?

A: High-grade steel construction offers enhanced durability, resistance to deformation, and long-term stability, crucial for maintaining accuracy and safety under high-speed, heavy-duty operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Speed Press Category

KYORI Used High Speed Press

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Product Type : KYORI Used High Speed Press

Application : Industrial

1066 NAGAO High Speed Press

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Product Type : HIGH SPEED PRESS

Application : Sheet Metal Forming

Voltage : 220V / 380V

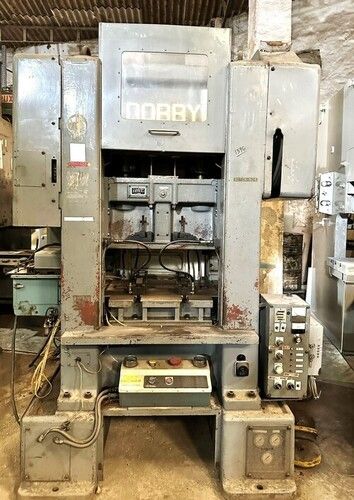

1403 DOBBY HIGH SPEED PRESS

Price 2850000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Product Type : HIGH SPEED PRESS

Application : Textile Industry Dobby Attachment and Processing

Voltage : 220 V

1396 DOBBY HIGH SPEED PRESS

Price 1800000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Product Type : HIGH SPEED PRESS

Application : Industrial Sheet Metal Pressing

Voltage : 440 V

|

MARVEL MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry