1441 AMADA H FRAME DOUBLE CRANK PRESS

Price 5300000 INR/ Unit

1441 AMADA H FRAME DOUBLE CRANK PRESS Specification

- Material

- Mild Steel

- Power

- 110 Ton

- Voltage

- 415 V

- Dimension (L*W*H)

- 2450 x 1420 x 3100 mm

- Application

- Sheet Metal Punching, Forming, Stamping

- Accessories

- Main Motor, Control Panel, Die Cushion, Lubrication System

- Stroke per Minute

- 30 SPM

- Type

- Double Crank H Frame Power Press

- Ram Adjustment

- 100 mm

- Shut Height

- 500 mm

- Model

- 1441

- Table Size

- 1800 x 800 mm

- Stroke Length

- 250 mm

- Max Die Weight

- 1000 kg

- Bed Opening

- 900 x 400 mm

- Bolster Thickness

- 130 mm

- Slide Area

- 750 x 500 mm

1441 AMADA H FRAME DOUBLE CRANK PRESS Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Main Domestic Market

- All India

About 1441 AMADA H FRAME DOUBLE CRANK PRESS

H FRAME DOUBLE CRANK PRESS

AMADA JAPAN

MODEL: SW-200A

SKU # 1441

Brief Specifications/ Details

- Cap: 200Tons

- Stroke: 300mm

- Bed Size: 2100 x 1300mm

- RAM Size:1800 x 1000mm

- Die Height: 625mm

- Adjustment: 125mm

- SPM:25

Outstanding Performance and Durability

The 1441 AMADA Double Crank H Frame Power Press stands out for its superior durability and reliability. Constructed from high-quality mild steel, it is engineered to withstand demanding industrial environments. With a stroke length of 250 mm and a shut height of 500 mm, it effortlessly handles repetitive sheet metal tasks, ensuring stable and accurate operation during high-volume production runs.

Versatile Application in Metalworking

Designed for versatility, this press excels in sheet metal punching, forming, and stamping. The generous table size and substantial max die weight capacity enable users to work on a broad range of projects. Its high stroke per minute and efficient ram adjustment are tailored for both small batch and mass production needs, making it a cornerstone for manufacturing industries.

Advanced Features for Enhanced Efficiency

Equipped with essential accessoriesmain motor, control panel, die cushion, and a robust lubrication systemthe 1441 AMADA press maximizes efficiency and reduces downtime. These features support smooth operation, precise control, and extended machine life, empowering operators to maintain consistent and safe production workflows.

FAQs of 1441 AMADA H FRAME DOUBLE CRANK PRESS:

Q: How does the 1441 AMADA H Frame Double Crank Press operate for sheet metal forming?

A: The press utilizes a double crank mechanism to deliver uniform pressure across the die during the stroke, ensuring accurate and consistent shaping or punching of sheet metal. Its 110-ton power and sizeable table provide the capacity to handle various forming and stamping operations efficiently.Q: What are the key benefits of the die cushion and lubrication system included in the machine?

A: The die cushion improves forming accuracy by evenly distributing pressure, while the lubrication system ensures critical components remain well-oiled, minimizing wear and extending machine life. Together, they optimize operational performance and enhance productivity.Q: When should you adjust the ram, and what is the available adjustment range?

A: Ram adjustment is performed when accommodating different die heights or optimizing stroke depth for various applications. The 1441 AMADA press offers a ram adjustment range of 100 mm, enabling flexibility in processing diverse sheet metal sizes and shapes.Q: Where is the 1441 AMADA Double Crank H Frame Power Press best utilized?

A: This press excels in industrial settings such as metal fabrication plants, automotive component manufacturers, and sheet metal workshops. Its design and capabilities cater to both custom and mass production operations requiring robust forming, punching, and stamping.Q: What is the process for setting up the machine for a new sheet metal job?

A: Operators select and install the appropriate die, adjust the ram and shut height as specified, calibrate the control panel, and ensure the lubrication system is active. Safety checks are performed before starting, followed by gradual trial runs to ensure optimal performance.Q: How does the machines high stroke per minute contribute to manufacturing efficiency?

A: The 1441 AMADA press operates at up to 30 strokes per minute, facilitating faster cycle times and higher throughput. This rapid motion makes it suitable for high-volume manufacturing while maintaining precision and consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in H Frame Double Crank Power Press Category

DANLEY S2-800-144-60 Straight Side Double Crank Press

Price 4000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Application : Industrial

Product Type : DANLEY S280014460 Straight Side Double Crank Press

Kawasaki Straight Side Double Crank Press

Price 5500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Application : Industrial

Product Type : Kawasaki Straight Side Double Crank Press

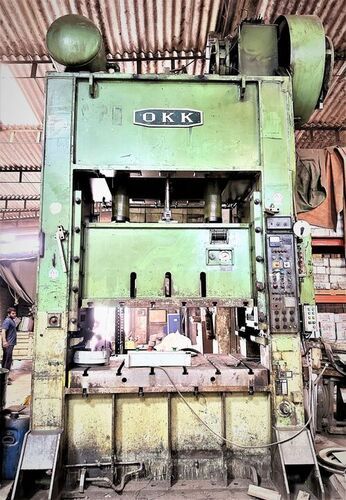

1286 OKK H FRAME DOUBLE CRANK PRESS

Price 5000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Application : Sheet Metal Stamping, Forming, Embossing

Voltage : 415 V

Product Type : H FRAME DOUBLE CRANK PRESS

1478 AIDA H FRAME DOUBLE CRANK POWER PRESS

Price 7500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Highgrade Steel

Application : Precision Metal Stamping, Automobile Parts Manufacturing, Large Component Forming

Voltage : 380 V

|

MARVEL MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry