1411 KURODA SURFACE GRINDER

Price 275000 INR/ Unit

1411 KURODA SURFACE GRINDER Specification

- Rotation

- Clockwise

- Model

- 1411 KURODA

- Product Type

- Used Surface Grinder

- General Use

- Surface Grinding

- Material

- Cast Iron

- Type

- Surface Grinding Machine

- Weight (kg)

- 1000 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Manual

- Table Size

- 150 mm x 400 mm

- Table Slide Way

- V and Flat

- Magnetic Chuck Size

- 150 mm x 450 mm

- Grinding Wheel Size

- 180 mm x 13 mm x 31.75 mm

- Grinding Wheel Speed

- 2850 RPM

- Grinding Length

- 300 mm

- Floor Space

- 1200 mm x 800 mm x 1400 mm

- Spindle Speed

- 2850 RPM

- Power

- 2 HP

- Voltage

- 415 V

- Dimension (L*W*H)

- 1200 mm x 800 mm x 1400 mm

- Feature

- Precision Grinding, Durable Construction

- Color

- Blue

- Coolant System

- Available

- Cross Feed on Table

- 150 mm

- Longitudinal Travel

- 400 mm

- Table Feed

- Manual

- Maximum Distance Center of Spindle to Table

- 300 mm

- Machine Condition

- Good Working Condition

- Lubrication System

- Automatic Pump

1411 KURODA SURFACE GRINDER Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Main Domestic Market

- All India

About 1411 KURODA SURFACE GRINDER

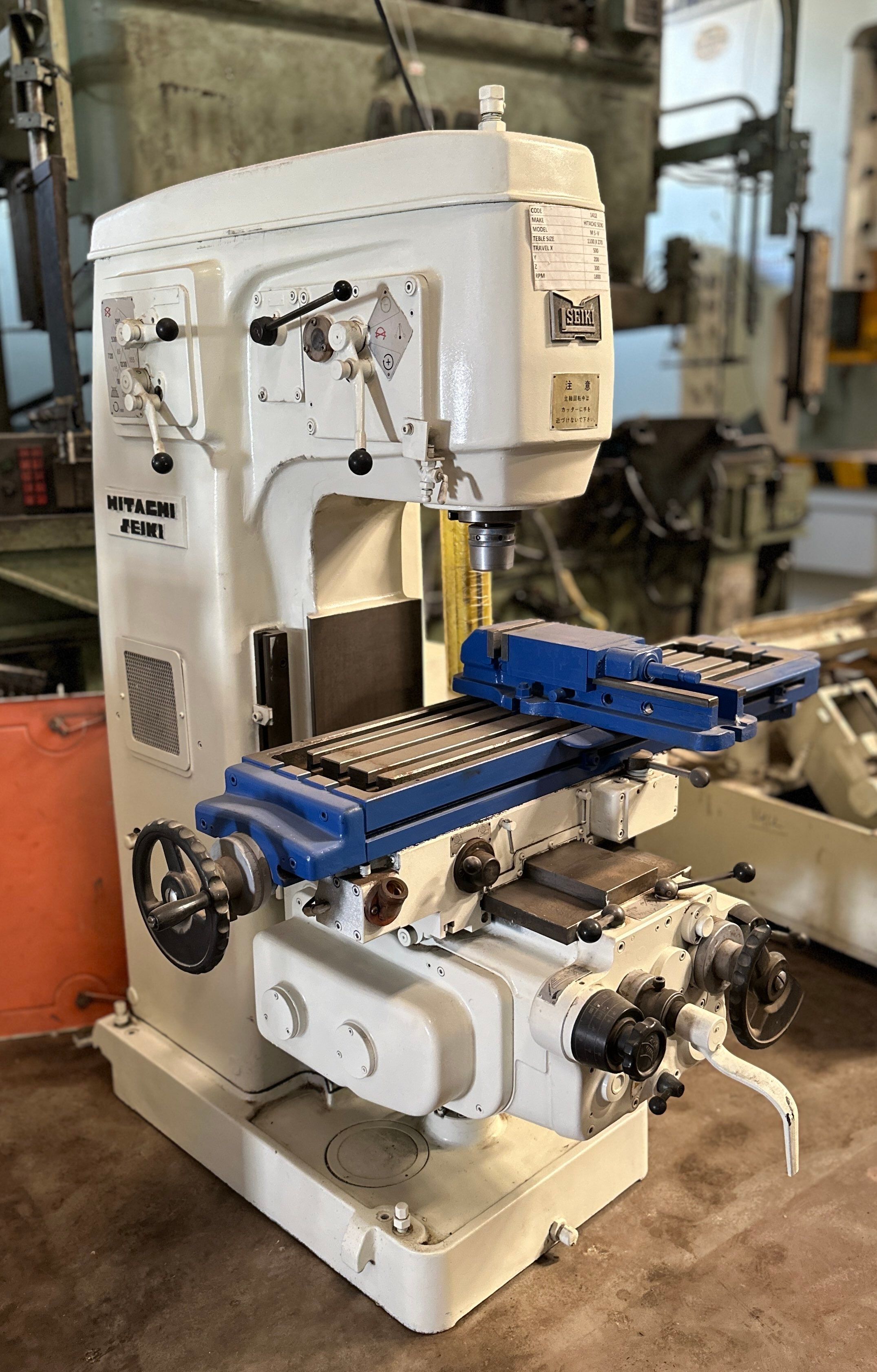

KURODA JAPAN MODEL GSBM2

HYD SURFACE GRINDER

KURODA JAPAN

MODELGSBM2

SKU 1411

Brief Specifications Details

Travel X550mm Y170mm Z250mm

Magnet Plate 380 x 110mm

Table Size 490 x 150

Accessories

Travel X Y Z Manual With Magnet Plate Coolant

Motor TankHydraulic Power Pack

Precision Grinding Made Easy

The 1411 KURODA Surface Grinder is engineered for high-accuracy machining tasks. Its manual controls allow for fine adjustments, and the automatic lubrication pump reduces maintenance downtime, ensuring seamless operation during prolonged use. Ideal for achieving tight tolerances and smooth finishes on a variety of workpieces.

Reliable and Durable Construction

Crafted from high-quality cast iron, this grinder promises excellent stability and vibration-free operation. The combination of a magnetic chuck and V & flat slide ways adds to its reliability, making it a trustworthy addition to any workshop targeting long-term productivity and durability.

Comprehensive Cooling and Lubrication Systems

With an integrated coolant system and an automatic lubrication pump, the 1411 KURODA minimizes heat buildup and friction during grinding, safeguarding both the machine and the workpiece. This helps maintain grinding accuracy and prolongs machine life, especially in demanding industrial environments.

FAQs of 1411 KURODA SURFACE GRINDER:

Q: How does the 1411 KURODA Surface Grinder ensure precision during operation?

A: The machine utilizes manual control for fine adjustment, a 150 mm x 450 mm magnetic chuck for secure workpiece holding, and robust V and flat slide ways, all contributing to precise, repeatable results in surface grinding tasks.Q: What is the maximum workpiece size the surface grinder can handle?

A: With a table size of 150 mm x 400 mm, a magnetic chuck of 150 mm x 450 mm, and a grinding length of up to 300 mm, the 1411 KURODA can accommodate a variety of medium-sized workpieces for diverse grinding applications.Q: When should I use the coolant system during grinding operations?

A: The coolant system should be used during all grinding processes to minimize heat generation, reduce thermal distortion in the workpiece, and extend the life of both the grinding wheel and the machine itself.Q: Where is the machine ideally installed for optimal operation?

A: The machine is best positioned in a well-ventilated, clean industrial environment with sufficient floor space of 1200 mm x 800 mm x 1400 mm, ensuring easy access for maintenance and operation.Q: What benefits does the automatic lubrication pump offer?

A: The automatic lubrication pump delivers consistent lubrication to critical components, reducing wear and maintenance needs, and supporting smooth and reliable long-term operation.Q: How is the table feed controlled on this machine?

A: The table feed is operated manually, providing the user with complete control over the grinding process and allowing for precise positioning suited to specific surface finishing requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Horizontal Surface Grinder Category

1433 NICCO KIKKAI HYDRAULIC SURFACE GRINDER

Price 525000 INR / Unit

Minimum Order Quantity : 1 Piece

Feature : Other, High precision, Low vibration, Rigid Structure

Material : Cast Iron

General Use : Industrial Surface Grinding

Computerized : No

1443 NAGASE SURFACE GRINDER

Price 725000 INR / Unit

Minimum Order Quantity : 100 Units

Feature : Other, Durable, Reliable Operation

Material : Other, Cast Iron and Steel

General Use : Industrial Surface Grinding

Computerized : No

1409 OKAMOTO SURFACE GRINDER

Price 950000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, Heavy Duty Construction, Precision Ground Components

Material : Other, Cast Iron & Alloy Steel

General Use : Surface Grinding of metals and hard materials

Computerized : No

1382 OKAMOTO SURFACE GRINDER

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, High Precision, Smooth Operation, Rigid Design

Material : Other, Cast Iron & Steel

General Use : Surface Grinding of Metal Components

Computerized : No

|

MARVEL MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry