MostPopularProducts

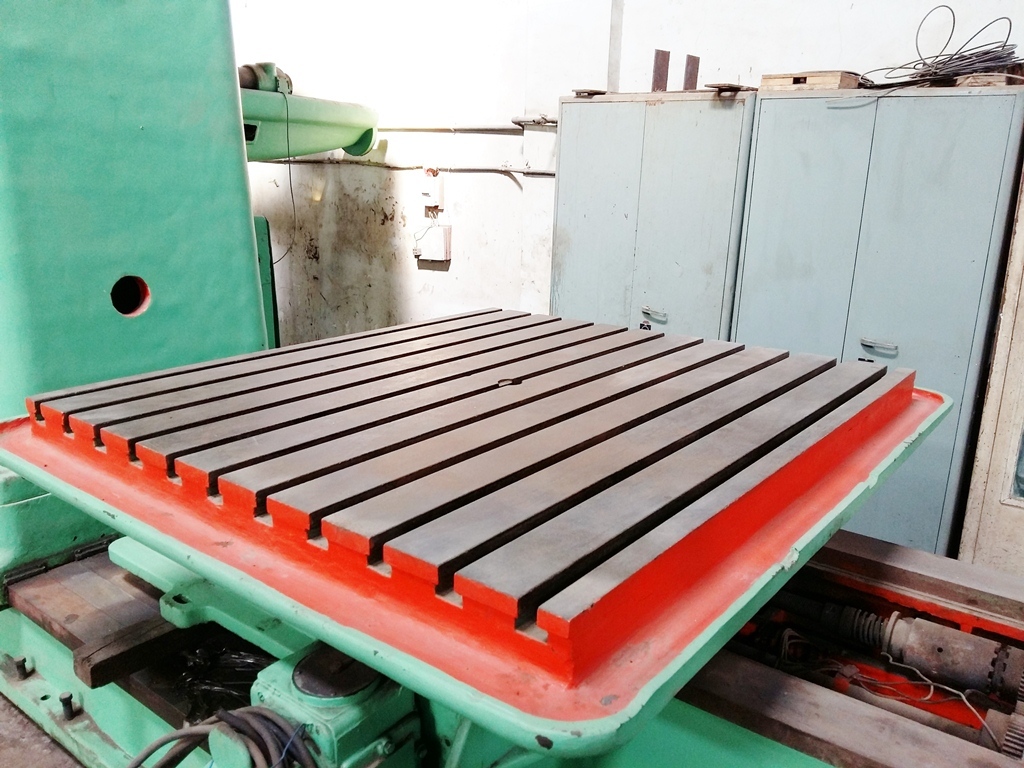

2346 WMW GERMANAY HORIZONTAL BORING MACHINE

Price 3500000 INR/ Unit

MOQ : 1 Unit

2346 WMW GERMANAY HORIZONTAL BORING MACHINE Specification

- Cutting Speed

- Variable

- Spindle Speed

- 201200 RPM

- Tool Type

- Boring

- Application

- Industrial, Metalworking, Engineering Workshop

- Power Source

- Electric

- Noise Level

- Low

- Product Type

- Horizontal Boring Machine

- Material

- Cast Iron, Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Manual

- Drive Type

- Gear Driven

- Voltage

- 415V

- Weight (kg)

- Approx. 6500 kg

- Dimension (L*W*H)

- 3500 mm x 2100 mm x 1700 mm

- Capacity

- Bore diameter up to 160 mm

- Feature

- Heavy Duty Construction, High Precision

- Color

- Industrial Green

- Cross Travel

- 1600 mm

- Longitudinal Travel

- 2500 mm

- Traverse Motor Power

- 7 kW

- Year of Manufacture

- 1990

- Spindle Taper

- ISO 50

- Coolant System

- Fitted

- Condition

- Used / Good Working

- Lubrication

- Centralized

- Max Table Load

- 4000 kg

- Spindle Travel

- 800 mm

- Table Size

- 1250 mm x 1500 mm

2346 WMW GERMANAY HORIZONTAL BORING MACHINE Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Main Domestic Market

- All India

About 2346 WMW GERMANAY HORIZONTAL BORING MACHINE

Horizontal Floor Borer

WMW GERMANY

MODEL W160

SKU 2346

Brief Specifications Details

Spindle Dia 160mm

Longitudinal Travel 3000mmExtendable

Vertical Travel 2050mm

Spindle Travel 1200mm

Rotary Table 1800 x 1800mm

Floor Plate 5300 x 1800mm

Facing Chuck 825mm

Rotary Angel 360

Main Motor 25HP

Rotary Table Motor 5HP

Heavy Duty Engineering Performance

Engineered for reliability and strength, the 2346 WMW Germany Boring Machine delivers high-precision results for metalworking and engineering operations. Capable of handling heavy loads, its cast iron and steel compatibility ensures adaptability for various workshop applications. The centralized lubrication and robust construction minimize maintenance and prolong operational life.

Designed for Versatility and Capacity

Boasting a large workspace and a boring capacity up to 160 mm in diameter, this machine accommodates bulky and complex workpieces with ease. Its variable speed controls, adjustable spindle travel, and manual gear-driven system give users precise command over each machining operation, maximizing productivity and accuracy.

FAQs of 2346 WMW GERMANAY HORIZONTAL BORING MACHINE:

Q: How is the 2346 WMW German Horizontal Boring Machine operated?

A: This machine utilizes a manual control system with gear-driven mechanisms, enabling operators to set spindle speeds, feed rates, and travel distances according to the requirements of each task. The semi-automatic grade allows for efficient yet precise operation.Q: What kinds of materials can this horizontal boring machine process?

A: It is built to bore and machine cast iron, steel, and similar metals, making it suitable for diverse industrial, metalworking, and engineering workshop applications.Q: When is this machine most beneficial in a workshop setting?

A: The machine proves most advantageous when high precision, heavy-duty boring of large or dense components is required, particularly for custom fabrication, repair, or manufacturing projects within its table size and weight limits.Q: Where should the 2346 WMW machine be installed for optimal use?

A: It should be placed in a well-ventilated, level area of an engineering or metalworking workshop with sufficient space for its 3500 mm x 2100 mm x 1700 mm footprint and proximity to a 415V electric power supply.Q: What is the process for changing spindle speeds or tool adjustments?

A: Spindle speeds are manually adjustable within the 201200 RPM range through the geared mechanism. Tool changes require stopping the spindle, manually releasing the current tool from the ISO 50 taper, and securely installing the next tool as needed.Q: How does the centralized lubrication system benefit usage?

A: The centralized lubrication system ensures that all essential moving parts receive consistent lubrication, reducing wear and tear, minimizing downtime for maintenance, and extending the machines lifespan.Q: What advantages does this used 1990 model offer compared to newer alternatives?

A: Despite its age, the machine delivers dependable heavy-duty performance, proven reliability, and high-precision results at a lower investment cost. Its robust construction and good working condition provide a cost-effective solution for demanding industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Horizontal Borer Category

1927 GILLY BELGIUM HORIZONTAL BORING MACHINE

Price 1300000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Other, Handoperated controls

Capacity : Heavyduty

Product Type : Horizontal Boring Machine

Spindle Speed : Variable, up to 420 RPM

|

MARVEL MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry